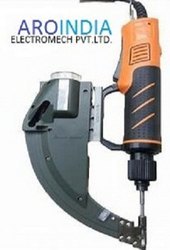

Semi Automatic Screw Feeder

Price 170000.0 INR/ Piece

Semi Automatic Screw Feeder Specification

- Color

- white

- Type

- Other

- Material

- iron

- Power Source

- 110~220v

- Rated Power

- 60w

- Product Type

- screwing

- Voltage

- 220v Volt (v)

- No Load Speed

- 300 RPM

- Weight

- 8 Kilograms (kg)

Semi Automatic Screw Feeder Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 10 Pieces Per Week

- Delivery Time

- 1 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- box -pneumatic pipe, screw feeder & screw driver

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Semi Automatic Screw Feeder

Operation:Hand-held Semi-automatic screw machine feeds screws in a turbine way and order screws on avibration guide rail, and transport screws between feeder to Screw driver nozzle through Pneumatic pressure and holding screw at nozzle by magnetic resonance, then one screw per time comes to screwdriver nozzle, finally electric screwdriver will fix the screw into products.

Product Specification

| Usage/Application | Automatic Screw Machine |

| Model Number/Name | ARO-SASM 01 |

| Brand | ARO |

| Capacity | 1 |

| Packaging Material | 1 box |

| Weight | 8 kg |

| Application | Automatic Screw Machine |

| No Of Head | 1 |

| Automation Grade | Semi-Automatic |

| Minimum Order Quantity | 1 Piece |

Innovative Assembly Efficiency

Elevate your manufacturing or repair tasks with the Semi Automatic Screw Feeder, designed for consistent and rapid screw dispensing. Its robust iron build ensures longevity, while the adjustable voltage offers versatility across different work environments. The optimal no-load speed makes it perfect for repetitive tasks where precision and time-saving are crucial.

User-Friendly Operation and Versatility

This screw feeder supports user convenience and is straightforward to integrate into your setup. Its compact size and manageable weight allow for easy relocation, making it a suitable choice for workshops, factories, and service centers. The devices compatibility with 220v power sources ensures it can be used in most industrial locations throughout India.

FAQs of Semi Automatic Screw Feeder:

Q: How does the Semi Automatic Screw Feeder improve assembly line efficiency?

A: By consistently dispensing screws at a speed of 300 RPM, the feeder reduces manual intervention, helps avoid delays, and enhances productivity during assembly operations.Q: What is the recommended power source for this screw feeder?

A: The device operates safely with a voltage range of 110 to 220 volts, making it compatible with standard industrial electrical setups in India.Q: When should I use a semi automatic screw feeder in my workflow?

A: This feeder is most beneficial during repetitive or high-volume assembly tasks where rapid and accurate screw fastening is essential for maintaining quality and output.Q: Where is the Semi Automatic Screw Feeder commonly used?

A: It finds applications in factories, workshops, electronics assembly units, and repair centers throughout India, especially where efficiency and consistency are valued.Q: What is the process for setting up and operating the screw feeder?

A: Simply connect the feeder to a suitable power source, load the screws into the designated compartment, and activate the unit to start feeding screwsminimal training is required for operation.Q: What are the main benefits of choosing an iron-bodied screw feeder?

A: Iron construction offers durability and a longer lifespan, withstanding frequent use and minimizing wear in demanding industrial environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Screw Driver and Screw Machine Category

Self Feeder Screw Driver

Price 12000 INR / Piece

Minimum Order Quantity : 1 Piece

Color : BLACK

Material : PLASTIC

Anti Static Plastic Screw Tray

Price 600 INR / Piece

Minimum Order Quantity : 5 Pieces

Color : BLACK

Material : ESD Plastic

Product Type : SCREW TRAY

Size : 435 x 280 x 62 mm

Electric Screwdriver Bits

Price 120 INR / Piece

Minimum Order Quantity : 10 Pieces

Color : Silver

Material : Mild Steel

Size : ALL TYPE

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS