BGA Rework Station With Touch Screen

Price 125000 INR/ Piece

BGA Rework Station With Touch Screen Specification

- Operating Voltage

- 800 Watt (W)

- Application

- Hot air

- Usage

- Industrial

- Size

- L605*W600*H520mm

- Height

- 520 Millimeter (mm)

- Weight

- 30 Kilograms (kg)

- Color

- Black

- Width

- 600 Millimeter (mm)

- Length

- 605 Millimeter (mm)

BGA Rework Station With Touch Screen Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 1 Piece Per Week

- Delivery Time

- 1 Week

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- Packing list 1pcs BGA Rework Machine, 1pc brush pen, 1pc sensor wire, 1pc instruction book, 1pc CD video, 1pc vacuum needle, 3pcs vacuum sucker, 3pcs top nozzle: 31*31mm, 38*38mm, 45*45mm, 2pcs lower nozzles: 34*34mm, 55*55mm 6pcs universal fixture, 6pcs fasten screw4pcs, support screw, 1 pc tweezer

- Main Domestic Market

- All India

About BGA Rework Station With Touch Screen

- Adopted with Linear slider, so all the three axles (X, Y, and Z) can do fine tuning and quick orientation with perfect positioning accuracy and speedily maneuverability

- Equipped with touch panel interface and PLC controlling to ensure it work stably and reliably. And it can storage multiple temperature profiling data of users. With password protection and modification function while power on. The temperature profiles will be displayed on the touch screen.

Product details

| Frequency | 50/60 Hz |

| Power | 4800 W |

| Top heater | Hot air 800 W |

| Upper Heating Power | 800 W |

| Automation Grade | Semi-Automatic |

| Brand | ARO |

| Input Voltage | 230V |

| Power Consumption | 4800 W |

| Model Name/Number | WDS 430 |

| Automatic Grade | Semi-Automatic,Automatic |

Advanced Touch Screen Operation

Navigate and control the BGA Rework Station with ease using its modern touch screen. The intuitive interface streamlines settings adjustments, allowing technicians to select temperature, airflow, and timing parameters quickly, ensuring precision and reducing the risk of user error during complex rework processes.

Efficient Industrial-Grade Performance

Powered by 800 watts and crafted for durability, this station can handle intensive production line use. The hot air application offers reliable soldering and desoldering for BGA components, making it indispensable for electronics repair workshops, manufacturing units, or any facility engaged in circuit board maintenance.

FAQs of BGA Rework Station With Touch Screen:

Q: How does the touch screen benefit the operation of the BGA Rework Station?

A: The touch screen enables easy customization of temperature, airflow, and timing settings, which improves accuracy and efficiency during reworking processes and minimizes operator mistakes.Q: What types of industrial applications is this BGA Rework Station suitable for?

A: This station is designed for electronic repair, manufacturing, and maintenance tasks that involve BGA components or require precise hot air soldering and desoldering on circuit boards.Q: When should I use the BGA Rework Station for hot air applications?

A: Utilize this station whenever you need to remove or attach BGA or other sensitive components on circuit boards, especially when traditional soldering tools cannot provide even heat distribution.Q: Where can this BGA Rework Station be effectively deployed?

A: It is ideal for electronics workshops, manufacturing lines, and industrial repair centers, especially those handling high-volume rework jobs or requiring equipment sourced from China.Q: What is the process for using the BGA Rework Station?

A: Begin by placing the circuit board on the work platform, then select the required settings using the touch screen. The station will direct hot air precisely to the desired area for controlled soldering or desoldering.Q: What are the benefits of using a hot air BGA Rework Station over traditional soldering methods?

A: Hot air rework provides even heating, reduces component damage risks, and enables reliable reworking of complex, surface-mounted packages that are difficult to handle by conventional soldering irons.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Soldering Stations Category

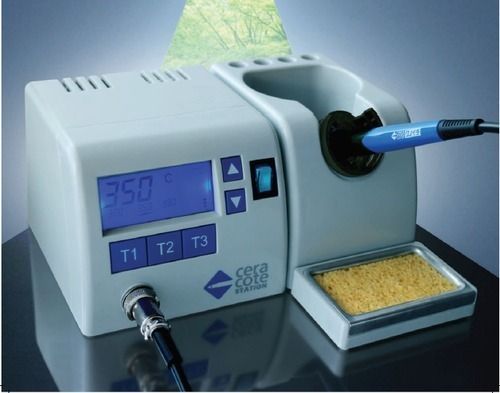

Soldering Station Cera Cote (Japan) Kunoichi 70w

Price 12000 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : SOLDERIING

Application : INDUSTRIAL

Color : White

Product Type : INDUSTRIAL

Soldering Station 60 W ARO 936A

Price 2600.0 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : soldering

Application : soldering

Color : black

Product Type : soldering temp controller

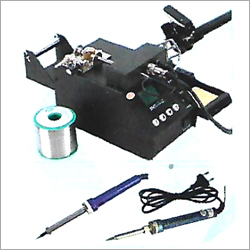

Semi Automatic Soldering Station

Price 40000 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : SOLDERING IN ALL PCB AND WIRE

Color : BLACK

Product Type : SOLDERING TEMP CONTROL

BGA Rework Station ARO-853A

Price 12000 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : INDUSTRIAL

Application : MANUAL

Color : BLACK

Product Type : MANUAL

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free